Description

Product Description

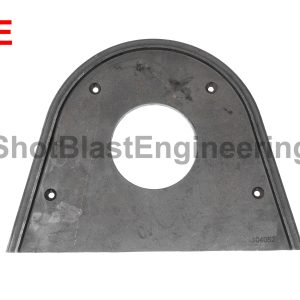

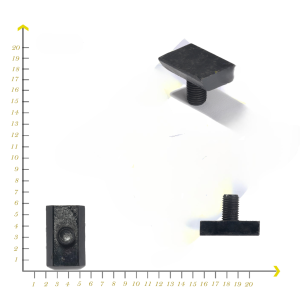

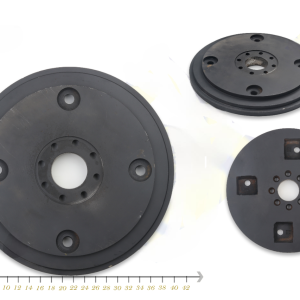

Product Name: Control Cage BMD

Product Code / SKU: 104137 / CA105415

Category: BMD SRD380 Spare Parts

Material: Chromium 18 Molybdenum (Cr18Mo) and Chromium 25 (Cr25)

Manufacturing Method: Silica Sol process

Weight: ≈ 2 kg

Features & Benefits

High-performance material: Constructed using Cr18Mo and Cr25 alloys, offering excellent wear resistance and mechanical strength.

Precision casting (Silica‐Sol method): Ensures excellent dimensional accuracy and surface finish, minimizing defects and extending lifespan.

Compatibility: Designed specifically for the BMD SRD380 series, ensuring perfect fit and optimal operation.

Durability & reliability: Engineered for heavy-duty shot blasting environments, reducing downtime and maintenance costs.

Applications

The Control Cage BMD is used in shot blasting machines (BMD SRD380 series) to control and guide components within the blasting chamber. It is an essential spare part for maintaining machine precision and extending component lifespan in abrasive environments.

Technical Specifications

| Specification | Details |

|---|---|

| Product Code | 104137 / CA105415 |

| Material | Cr18Mo, Cr25 |

| Manufacture Method | Silica Sol casting |

| Weight | Around 2 kg |

| Compatible Machine | BMD SRD380 |

Why Choose This Control Cage?

Reduced wear due to high-grade chromium‐molybdenum alloy

Better resistance against abrasive and impact forces

High precision casting ensures easier and more secure installation

Minimizes operational interruptions by providing long service life

Frequently Asked Questions (FAQs)

Is this control cage compatible with machines other than BMD SRD380?

Answer: This model is specifically designed for the BMD SRD380 series. Compatibility with other models would depend on exact dimensions and assembly specifications; please refer to your machine’s spare part manual or contact technical support.What is the expected lifespan of this control cage under normal operation?

Answer: Lifespan depends on operating conditions such as abrasive type, intensity, frequency of use, and maintenance. With proper care and regular inspection, it should offer long service intervals. For harsh conditions, more frequent checks are recommended.How do I maintain or clean the control cage to ensure optimal performance?

Answer: Periodic inspection for signs of wear or damage; removal of accumulated debris; ensure correct alignment when re-installed. If there are any cracks or excessive wear, replacement is recommended.Can I get this product in different material grades or thicknesses?

Answer: Currently available in Cr18Mo and Cr25 with the thickness/manufacturing as per design. For custom material or specification requests, please contact the manufacturer or sales department for possible custom orders.What is the shipping time and cost for international orders?

Answer: Shipping time and cost depend on destination, weight, customs, and shipping method. The product weighs approx. 2 kg; contact the supplier with your address to get a shipping quote.

Reviews

There are no reviews yet.