ABOUT US

Company Profile:

SBE Precision Casting Co., LTD, established in 2007 in Zibo City, Shandong Province, is dedicated to the research, development, and manufacturing of high-quality wear-resistant parts, particularly high chromium cast iron components. Our expertise extends to producing premium shot blasting machine spare parts and a variety of steel abrasives, including high carbon steel shot, low carbon steel shot, steel grit, bearing steel grit, carbon steel cut wire shot, and stainless steel cut wire shot.

At SBE, we take immense pride in ensuring the quality and reliability of our products, driven by our relentless pursuit of excellence. We offer a comprehensive range of shot blasting machine spare parts and other wear-resistant components, specializing in developing optimal solutions to enhance our customers’ total cost of ownership

SBE Precision Casting Co, established in 2007 and located in Zibo City, Shandong Province, China. Over the years, we have developed a unique manufacturing technique and lean management system. Our commitment to excellence drives us to ensure the quality and reliability of our products consistently.

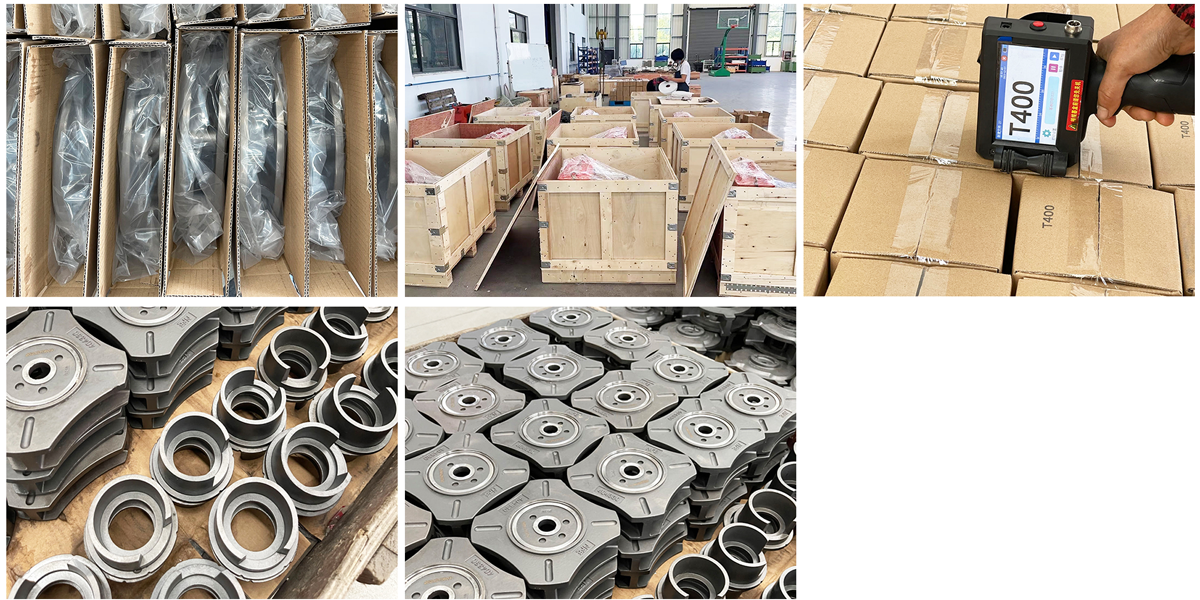

Shot Blast Machine Spare Parts:

SBE specializes in providing a wide range of spare parts for shot blasting machines and other wear-resistant components. We are dedicated to developing optimal solutions that enhance our customers’ total cost of ownership. For the past 20 years, we have upheld a people-oriented approach and a commitment to integrity, strictly adhering to safety, environmental protection, and occupational health regulations. We strive to improve our employees’ working conditions to enhance their overall experience. Our team boasts extensive experience in the casting industry and excels at developing products tailored to customer needs, fostering strong cooperative relationships. We consistently deliver top-notch service and explore new applications for precision casting.

SBE manufactures and sells high-quality wear-resistant parts for shot blasting machines at competitive prices. Our team of highly skilled engineers is adept at overcoming any challenges. Utilizing the Silica Sol and Coated Sand foundry methods, we have earned ISO9001 Quality Management System certification. Our comprehensive testing facilities, including Spectrum Analyzers, Hardness Testers, and Metallographic Analyzers, ensure strict production management and product quality. Maintaining a permanent stock of spare parts allows us to provide prompt delivery. Our wear-resistant parts for globally recognized blast equipment have earned the trust and loyalty of customers worldwide.

Steel Abrasives:

Our company leverages advanced equipment and technology, coupled with rigorous quality control methods. Utilizing Centrifugal Atomizing, Double Quenching, and Low-temperature Tempering, our steel abrasive products are meticulously produced and tested in accordance with standards such as SAE J444.

Renowned for their superior quality, competitive pricing, and exceptional service, our abrasive products are extensively used in industries including automotive, shipbuilding, steel structures, and metallurgy. We proudly export to over 30 countries and regions, including North America, Europe, the Middle East, and Southeast Asia.