Description

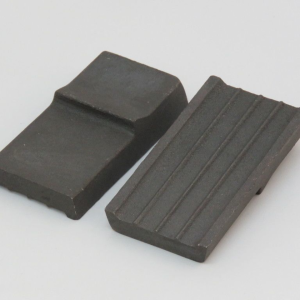

Alju Impeller for Shot Blast Machines — High Durability & Superior Performance

Product Overview

The Alju Impeller, is a high-performance spare part designed for shot blast machines. Manufactured using the advanced Silica Sol process, this impeller provides exceptional wear resistance, structural integrity, and long service life. With a weight of approximately 2.9 kg, it delivers the perfect balance between durability and efficiency in blasting operations.

Key Features

Silica Sol Casting: Ensures a denser structure, improved toughness, and enhanced resistance against abrasion.

Optimal Weight (2.9 kg): Provides the right balance between strength and performance without overloading the turbine.

High Wear Resistance: Engineered to withstand continuous impact from steel shots and abrasive particles.

Perfect Compatibility: Designed for Alju shot blast machines and compatible turbines.

Improved Efficiency: Reduces vibration, lowers noise levels, and increases machine uptime.

Benefits

Longer Service Life → Less downtime and fewer replacements.

Cost Savings → Reduced maintenance and lower operational costs.

Consistent Performance → Stable blasting quality across long production runs.

Enhanced Safety → Balanced design minimizes vibration and mechanical stress.

Applications

Metal & Steel Industry

Automotive Manufacturing & Parts Production

Foundries & Casting Workshops

Marine & Shipbuilding Industry

Heavy Machinery Maintenance

Technical Specifications

| Specification | Value |

|---|---|

| Weight | 2.9 kg |

| Manufacturing Process | Silica Sol |

| Material | Special wear-resistant alloy |

| Suitable For | Shot blast turbines & industrial blasting equipment |

Installation & Maintenance Tips

Clean the impeller thoroughly before installation.

Ensure proper alignment and balancing to avoid vibration.

Tighten bolts with the recommended torque values.

Inspect regularly for signs of wear, cracks, or imbalance.

Replace immediately if performance decreases or damage is detected.

Frequently Asked Questions (FAQ)

1. What makes Silica Sol casting better than traditional methods?

Silica Sol casting produces a smoother surface finish, higher precision, and superior resistance to cracking and wear compared to conventional casting methods.

2. When should I replace my impeller?

When you notice excessive wear, cracks, imbalance, unusual noise, or reduced blasting efficiency.

Reviews

There are no reviews yet.